Blogs

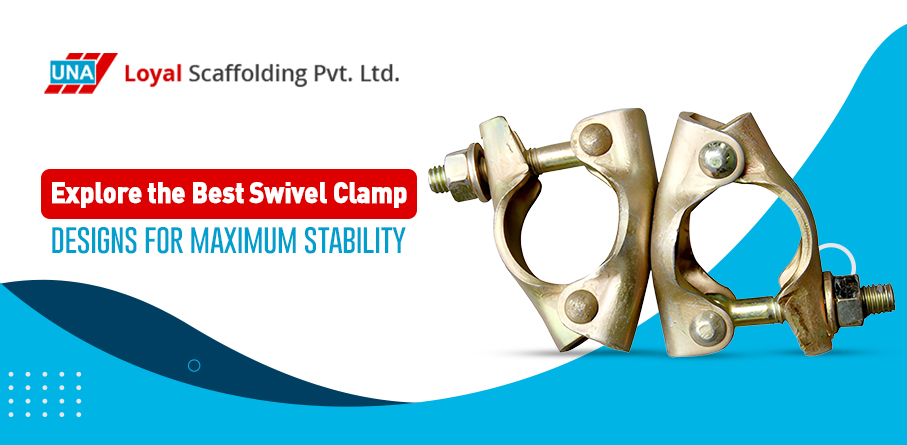

Explore the Best Swivel Clamp Designs for Maximum Stability

Swivel clamps are important tools for joining pipes, tubes, and structural parts at different angles in building, scaffolding, metal fabrication, and other industrial settings. When compared to fixed clamps, their ability to move freely makes them very flexible. This lets workers make safe, flexible connections without sacrificing stability.

Today's building needs both accuracy and flexibility, so swivel clamp designs have changed to make them stronger, better at spreading loads, and safer. Knowing the best swivel clamp designs can help pros and engineers pick the right hardware for long-term use and structural stability.

What's so great about swivel clamps?

Swivel clamps are great because they can turn all the way around. Pipes and scaffolding tubes can be joined at any angle thanks to this design. This makes them useful for building irregular structures, temporary frames, and custom supports. If the swivel clamp is well made, the joint will not come loose, even if there is a lot of force or shaking. The clamp's locking mechanism, which is usually a set of forged or pressed steel parts connected with high-tensile bolts, holds the structure tightly and keeps it stable.

These days, swivel clamps focus on tightening securely, not rusting, and moving smoothly when rotating. A rotatable pivot and strong fastening capabilities make it possible for users to build hard structures that are still flexible during installation.

Heavy-duty forged steel swivel clamps are the norm

Many people think that forged swivel clamps are the most reliable choice for tough settings. Their production process makes them denser and more structurally stable, so they can hold heavy loads without deforming. These clamps are perfect for scaffolding, industrial platforms, and repair structures that need to be as stable as possible.

Because they are so strong, forged clamps don't slip much, even when things are moving. Because they last a long time, they can be used more than once, which saves contractors and industry operators money in the long run.

Stainless steel swivel clamps that are pressed are light and work well

When weight is important, pressed steel swivel clamp manufacturers are the best choice. They are stronger and more reliable than forged clamps, but they are lighter. They can be used for general building and light to medium industrial work. Their simple design makes them easier to place, and they're flexible enough for structures that don't need to hold a lot of weight.

Because they are lighter, pressed steel clamps are also easier to use in tight or high places, which makes installation safer overall.

Galvanized swivel clamps will last for a long time

A lot of people use galvanized swivel clamps because they don't rust, which is important in outdoor and commercial settings. Because the zinc coating keeps the metal from rusting, getting wet, or being exposed to chemicals, these clamps are good for coastal areas, chemical plants, and long-term scaffolding setups.

For long periods of time, galvanized swivel clamps keep structures stable, which cuts down on upkeep needs and prevents safety problems that can happen when joints become weak.

In the end

When it comes to building, industrial work, and custom structural setups, the best swivel clamp designs strike a balance between strength, flexibility, and durability. Each design has its own purpose, such as being forged for heavy-duty use, pressed for lightweight efficiency, galvanized for environmental protection, or designed so that angles can be changed.

The right swivel clamp should be chosen based on the load, the surroundings, and the structure. When you choose the right ones, swivel clamps give you a safe, stable base for working on your project quickly and safely.

TRENDING POST

RECENT POSTS

NEWSLETTER

Subscribe my Newsletter for new blog posts. Stay updated from your inbox!

.jpg)

Leave a Comments