Blogs

Affordable Aluminum Cantilever Tower Solutions for Industrial Sites

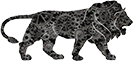

Aluminum cantilever tower is now an essential tool for high-level work in commercial settings that value safety, accessibility, and efficiency. These towers provide a safe place to work at height for jobs such as maintenance, installation, inspection, and repair. Their success stems from their light weight, rust resistance, and ease of movement. This makes them ideal for industrial use both indoors and outdoors. As businesses seek safer, more cost-effective ways to work, inexpensive metal cantilever towers stand out as a good buy.

Why Should You Pick Aluminum Cantilever Towers?

Cantilever towers made of aluminum are practical and long-lasting, making them suitable for many industrial settings. Steel scaffolding can be heavy and hard to move. Aluminum Scaffolding Cantiliver Tower, on the other hand, is firm yet lightweight. This cuts down on the time it takes to set up and also makes it easier for workers to move towers around a place.

Aluminum is naturally resistant to rust and corrosion so that it will last longer even in harsh or humid conditions. This durability means that companies, refineries, and warehouses will incur lower repair and replacement costs. Cantilever shapes also make it easier to reach places that are hard to get directly below, such as the edges of machines, tanks, or installations above.

Design Elements That Make It Worth It

Modern Aluminum Tower is designed to be as safe and helpful as possible. Because they are made of separate modules, you can change their height and arrangement to fit the needs of any job. Most platforms have non-slip surfaces that prevent workers' feet from slipping while using tools or equipment.

These towers are safer because they have guardrails, toe boards, and locking systems. Many types come with outrigger stabilizers and base plates that can be adjusted to provide extra support on uneven ground. Also, most cantilever towers are easy to assemble without special tools, which saves teams time when setting up and taking down.

Another benefit is that they are small enough to store and move around easily. The pieces are light and can be put together in different ways, making them easy to move from one place to another or to store when not in use.

Savings on costs and long-term value

One big reason why metal cantilever towers are becoming more popular is that they are getting cheaper over time. It might seem more expensive than a steel support at first, but in the long run, it's worth it. Aluminum buildings don't need much upkeep; they don't need to be painted, rust-proofed, or have parts replaced often.

In industries where people regularly work at heights, such as manufacturing, chemical processing, or energy centers, this saves significant money. Because it's easy to move and assemble, it also costs less to hire workers, since less downtime is needed for setup or moving. A well-maintained metal cantilever tower can last for years, offering a great return on investment for businesses.

Standards for safety and compliance

In the business world, safety is paramount, and new Aluminum Scaffolding Cantiliver Tower on Hire are designed to meet the highest global safety standards. Towers built by reputable companies are designed to meet standards such as EN 1004 or OSHA rules, ensuring they can withstand weight, remain stable, and protect workers.

Slips and falls are less likely to happen at work when there are guardrails, connected frames, and anti-slip platforms. These towers will last for a long time as long as they are inspected regularly and used according to the instructions. Companies can stay up to date with regulations and maintain workers' trust by buying certified goods.

In conclusion

For industrial settings, cheap Aluminum Scaffolding Cantiliver Tower for Sale are the best combination of safety, mobility, and low cost. They make workers more productive, reduce setup time, meet the highest safety standards, and are built to last. These towers are a bright, long-lasting way for businesses to improve their operations without risking safety or budget. They are the perfect answer for today's business needs.

TRENDING POST

RECENT POSTS

NEWSLETTER

Subscribe my Newsletter for new blog posts. Stay updated from your inbox!

.jpg)

Leave a Comments